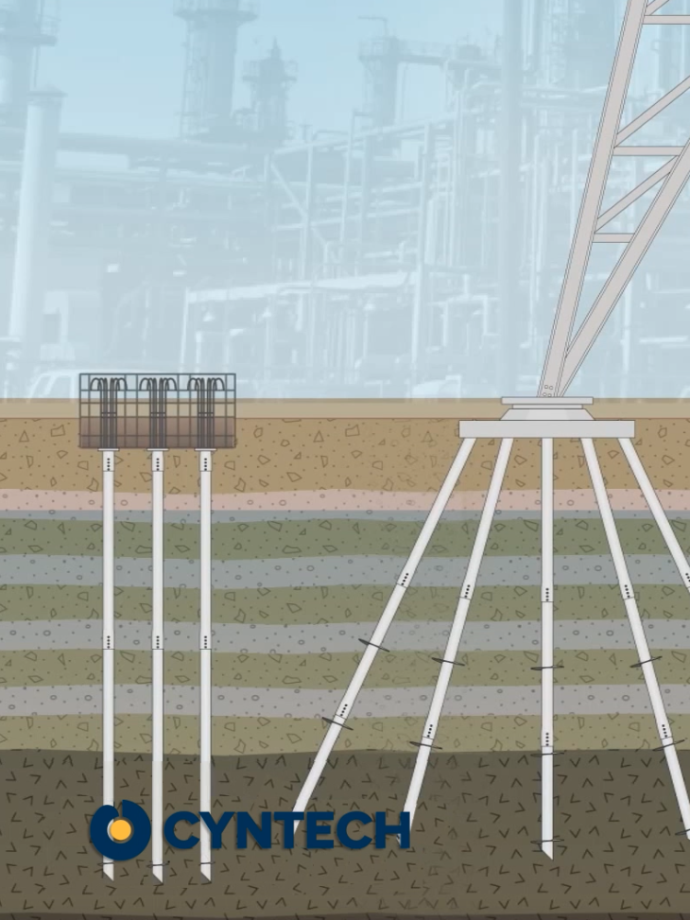

Helical piles, also known as helical piers or screw piles, are constructed using steel shafts with helical flights of various sizes to suit the site-specific ground conditions. They are a proven deep foundation solution ideal for energy, industrial and commercial applications.

Common uses

Process

Our engineers can design a custom foundation for your specific needs using standard soil test data.

Piles are generally installed using standard tracked or wheeled excavators with a torque motor attachment which monitors the torque achieved during installation to ensure predictable pile capacity. The final torque reading is taken over the last 1m of advancement to ensure the pile is achieving the required design before terminating at the correct datum level.

Helical piles are screwed into the soil, to the predetermined (design) bearing strata by rotating the steel shafts with the torque motor attached to the excavator plant/rig. They are not driven or vibrated, and don’t need a hole to be dug or drilled, so the soil around the pile remains undisturbed.

Multiple steel sections are connected via a bolted connection and sections are added to complete the total pile depth.

Individual helical piles are able to restrain unfactored (SWL) axial loads of up to 2000kN and lateral loads in excess of 250kN, both subject to geotechnical conditions. Significantly higher lateral forces can be resisted by battering the pile, or by incorporating a concrete collar to the upper portion of the pile.

A detailed understanding of the subsurface conditions – especially soil strata type, strata levels and strength (SPT ‘N’ Values) – to depth is necessary to properly interpret the required design and torque capacities.

On completion, the top of the pile can be connected in various ways to the structure by a direct steel flange plate connection or plate/rebar connection to concrete. Torque is monitored during installation to ensure predictable pile capacity, and we can achieve relatively high ultimate capacities, safely and economically.

A typical helical pile can be installed in minutes using standard equipment such as a pole line truck, excavator or backhoe.

Helical Pile Manufacturing

For all U.S. customers and projects, we manufacture 100% of our helical piles, pile extensions and pile caps in our Houston (Plantersville), Texas facility, whereas our Calgary, Alberta location services the Canadian and overseas markets. Our state of the art workshops include CNC-automated cutting, bending and welding to produce exact, uniform quality for all parts.

We produce all sizes and configurations of helical piles and pile caps, from 1.5 in (38 mm) and 1.75 in (44 mm) high-strength solid square bar anchors, right up to 42 in (1067 mm) diameter round shaft piles.

In total, our facilities share a combined fabrication capacity of over 50,000 tons/year, with the ability to quickly scale beyond on an as-needed basis. Having two fabrication facilities allows us to distribute work between both, enabling our teams to easily meet your project timelines.

Our quality program was created in full compliance of the ISO 9001:2015 Standard for Quality Assurance, providing continual improvement, consistency of service and product, and complete material traceability.

Advantages

Why choose us?

We have fabrication facilities in Calgary, Alberta, Canada and Houston, Texas, USA. We offer full traceability, Buy America, and third-party inspections in both facilities. Most of our pipeline buoyancy anchors are manufactured in our Canadian facility, but we can shift orders to either facility to meet scheduling requirements.

We have automated plasma tables, presses, and pipe profilers, that enable us to keep up with tight production rates, keep costs down, and maintain the design and quality parameters required.

Our welders are certified AWS in the US, and AWS, and CWB in Canada. We have certified welding supervisors and engineers assigned to each shop that monitor and maintain welding standards and procedures to ensure our quality meets your needs and industries standards.

For those projects that require additional corrosion protection, such as galvanizing or cold tar epoxy, we have developed partnerships locally that keep us cost effective while maintaining a continuous flow of material to the job site.

We partner with shipping professionals that understand our business and your expectations, whether you need it shipped across town, across country, or worldwide.